Abonnez-vous à notre Newsletter

Recevez nos nouveautés, catalogues et codes promo exclusifs !

Application: Recommended for unfilled plastics.

Options :

Application: Recommended for filled plastics.

Options:

Application: Recommended for reinforced plastics with over 30% glass fiber content.

Options:

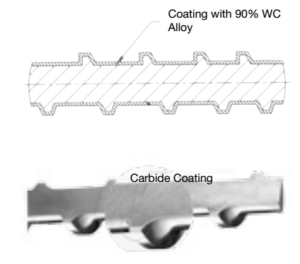

The microstructure consists of fine tungsten carbide particles measuring 2 to 5 microns, embedded in a cobalt-based alloy.

The hard metal is embedded in an elastic alloy and is characterized by high impact resistance. The risk of breakage is low. However, depending on the application, occasional breakage may occur, especially during high-temperature cleaning or if the screw is subjected to excessive bending stress.

Additionally, polycarbonate and other adhesives are not suitable.

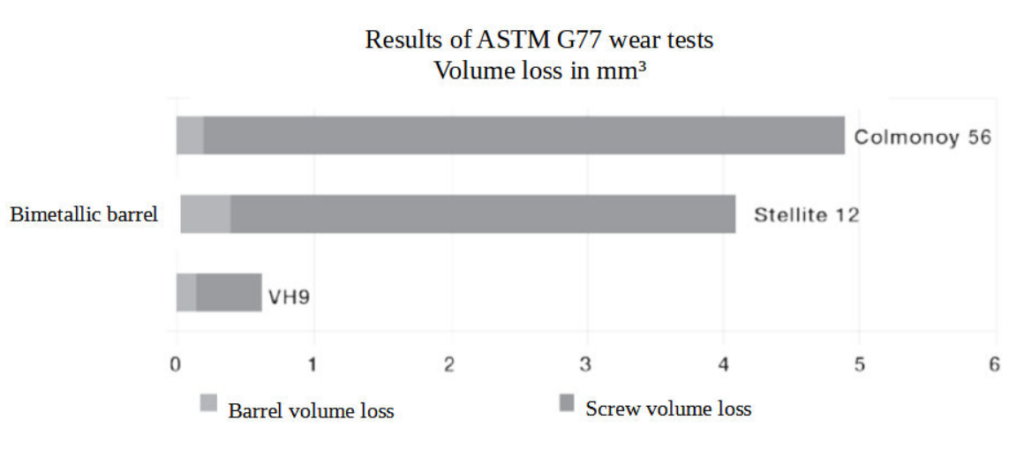

Contrary to expectations, alloys made from fine tungsten carbide powder particles are less aggressive on the barrel.

See abrasion tests performed according to ASTM G77.

Download the quotation request form below and send it completed to the email address commercial@abcdirect.eu

Recevez nos nouveautés, catalogues et codes promo exclusifs !